The 45-Second Trick For American Plastics

Wiki Article

American Plastics Can Be Fun For Anyone

Table of ContentsThe Single Strategy To Use For American PlasticsThe Greatest Guide To American PlasticsMore About American PlasticsLittle Known Questions About American Plastics.The Only Guide to American Plastics

A little research can help you in time. It is hard to evaluate its high quality initially glimpse with the appearance of HDPE pipeline fitting, many issues are revealed when using, so we can just have a proper judgment after usage. As a result, it is needed to select HDPE pipe fittings made by a specialist producer with a good credibility and credibility.

A technical professional is important for an excellent product, especially in the production industry, because a small blunder will certainly result in the failure of the whole project. HDPE pipelines can change concrete pipes in field systems to save time and expense of fixing broken or burst pipes. HDPE pipeline is also a less costly choice compared to other piping materials in regards to operating and installation costs.

5 Simple Techniques For American Plastics

HDPE pipelines are made with strong straight or curved sections. It is made of light-weight products that are simple to carry and does not require hefty setup tools such as heavy cranes. The mix of light-weight and flexible frameworks makes it excellent for earthquake-prone areas. The pipelines are not fragile and can be conveniently inserted right into a rounded location without added jointing or welding.It has reduced tension and stormy turbulence, particularly at high circulation rates. Its 'non-adhesive' characteristic makes it suitable for retaining the residential or commercial properties of hydraulic fluids. Also HDPE tin tubes are formed in two phases to ravel the inside. Chemicals resistant to HDPE pipes can pollute the pipeline. The pipe does not collaborate with chemicals and does not melt warm or electrical energy.

HDPE pipes are naturally strong and resistant to damage triggered by exterior tons, high pressure or vibration - https://www.smugglers-alfriston.co.uk/profile/danecoffman7970184804/profile. The pipelines can stand up to handling and bend also in winter. Safe eyeliner HDPE inner tubes Smooth Line Pipeline Gliding lining using roller mixes Pipeline explosion Plastic pipes systems Building and construction of new pipes Corrosion resistance, no dripping, high sturdiness

Heat combination, while its challenges exist, can create strong and reputable joints. Responses: The strength and sturdiness of HDPE can be measured by its capability to stand up to temperatures of around 248F in the brief term and even a continuous 230F. If your application consists of gas and fluid to accessibility and raise those temperatures, HPDE piping is a reputable solution.

A Biased View of American Plastics

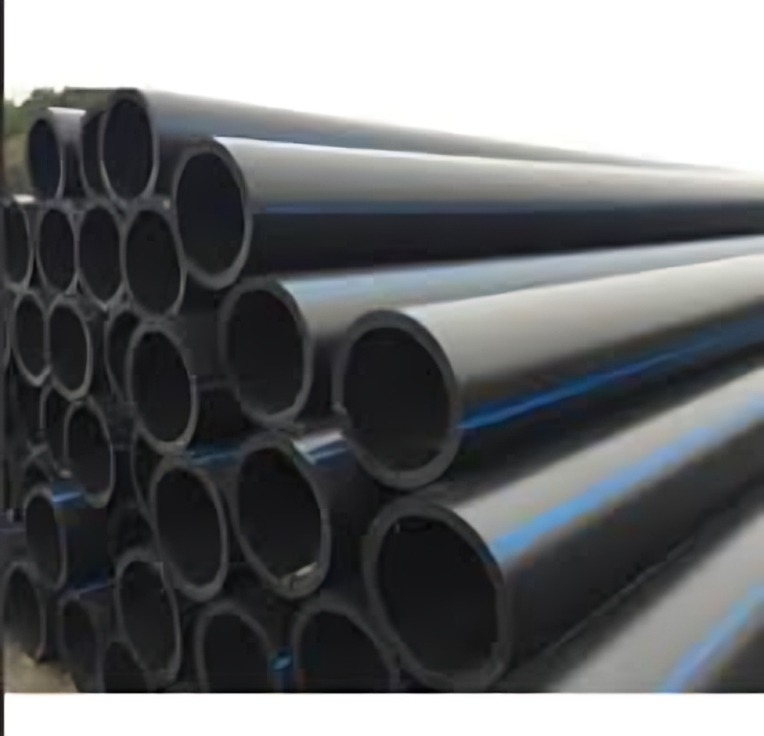

A potable water line/potable water pipe is always dark with blue stripes and pipelines passing through fluids, liquids under pressure, and procedure gases are always filled up with a yellow or black jacket with yellow lines. HDPE pipe material have been utilized in the general sector click this site for over half a century and their outcomes are astonishing, constructing confidence amongst makers that they are extra concentrated on HDPE pipe options.Times since 1991 Removal of material requirements with scale and change. In the anxiety fracture resistance examination the cellular division requirements were deteriorated. It is practical to wrap up that HDPE pipeline developed today may have.

Each size group is designed remembering the demands of pressure, circulation price, and ecological factors of the intended application. By matching the correct HDPE pipeline size to its use, designers and specialists can optimize performance and prolong the lifespan of their piping systems. Dimension and diameter are related concepts in the context of HDPE pipelines.

10 Easy Facts About American Plastics Described

As mentioned earlier, pipes with lower SDR values are able to withstand higher stress, which is an important consideration in the choice process for jobs that entail high pressure or crucial applications. high quality hdpe pipe. Choosing a pipeline with an improper SDR can cause system failing, safety and security dangers, and costly repair services. Picking the correct HDPE pipeline size is important for the success and effectiveness of any kind of piping system

Application Specifics: Customize your pipeline size choice to the specific demands of its application, whether for municipal, industrial, or other uses. Understanding just how the HDPE pipe will be utilized, the awaited flow rates and the stress demands are essential. High-pressure applications might require a pipeline with a greater wall thickness to endure the interior tensions, while a lower-pressure, high-flow system might prioritize diameter dimension to reduce rubbing loss.

What Does American Plastics Do?

Comply with these actions: Evaluate the Application: Identify the pipe's planned use, consisting of ecological elements and solution problems. Determine Flow Prices: Use industry-standard calculations or software application to estimate the peak and standard circulation prices. Understand Stress Requirements: Identify the stress score required based upon system needs. Refer to SDR: Check the conventional measurement proportion to locate a pipeline that can manage the needed stress.Picking the ideal HDPE pipe size is a fragile equilibrium in between countless technical specs and practical demands - https://www.lidinterior.com/profile/danecoffman7970175637/profile. With mindful consideration and precise estimations, you can make sure the size of the pipeline you choose will offer your needs efficiently and efficiently. Selecting the right HDPE pipeline size is essential for system performance, resilience, and cost-effectiveness

Comprehending these elements will make certain ideal efficiency and compatibility throughout your piping system - hdpe pipe suppliers Midland TX. The anticipated circulation price or volume of the fluid being moved is among the key factors in pipeline size option. A pipeline that is as well little can limit circulation, triggering stress loss and possible obstructions, while an overly big pipeline might result in unnecessary expenditure and minimized system performance

Report this wiki page